TGA Thermogravimetric Analyzer

TGA Thermogravimetric Analyzer is designed by measuring mass changes of samples at elevated temperature, which is mainly used to evaluate mass-temperature relations of samples. It is applicable perfectly for analyzing oxidation of materials containing carbon, carbonization and nitrification of different materials,ect. Moreover,it can test directly large particles or large bar sample which is not ground first.

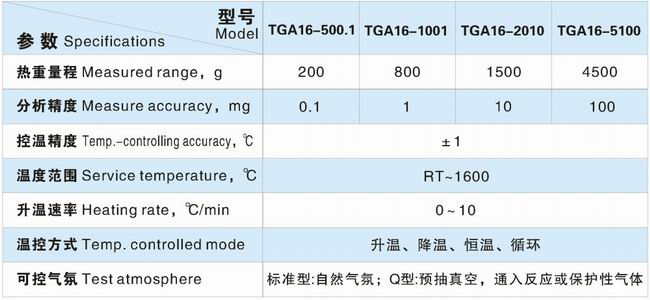

Main technical parameters

Heating

cooling

constant temperature

circulation

Standard type: natural atmosphere

Type Q: pre pumped vacuum, inlet the reaction or protective gas

Mainstream model equipment selection guidance:

Thermal weight range

analysis accuracy

Equipment brief introduction

Pouring material, ramming material and mineral raw materials, etc.,in the heating process,water or gas come out,the quality of the materials is reduced.Carbon containing materials in the heating process, because of oxidation,the weight reduce or increase; nitriding of SiC material under nitrogen environment.These changes in the heating process of the material, reflecting the special properties of the material.The instrument is under the control of microcomputer temperature program (constant heating, cooling, constant temperature and circulation), and through the test of the thermal stability of high quality (5-4500g) samples,to research the material’s:

★Adsorption and desorption ★Sintering process

★Quantitative analysis of carbon ★Oxidation and reduction

★Nitrogen saturation ★Antioxidant properties

★Free water and structural water content

★The failure characteristics of additives, fillers, binders

Instrument function:

1、Heating furnace structure

TGA-500.1, top hat furnace

TGA-500.1Q,core closed top hat furnace

TGA-1001/2010/5100 top hat or box furnace

TGA-1001Q/2010Q/5100Q top hat or box closed furnace

2、Lining and insulation materials

Heating-furnace: electric heating furnace with the lining using mosaic structure. The lining from the inside to the outside are used 1800℃ high temperature energy saving material,1500℃ heat-barrier material and 1000℃ heat-insulating material;the heating element is arranged on both sides of the furnace hearth, adopt U type Si2Mo,

the average temperature in the test area of the box furnace is less than 10℃, of the top hat furnace is less than 5℃.

Vacuum system:TGA-Q series,standard forvacuum, optional off-gas analysis or vacuum pyrolysis system

4、air-breather

A、

A. 2 way independent ventilation pipeline,both install rotor flow meter (accuracy of 5%), optional with mass flow meter

B、

B. Can inlet inert gas, CO, H2 or mixture gases, etc.

C、

C. Single gas or premixed gas by gradual heating into the furnace and diffuse,around the specimen formed the atmosphere,one exhaust port

D、

D. Optional tail gas treatment device when the CO and H2 gas are passed in

5、

5. The balance is positioned at the bottom of the furnace and has a temperature protection mechanism.

6、

6. The furnace has the function of fault couple protection and current limiting

7、

7. Temperature, pressure, flow rate and weight change rate are controlled by microcomputer.

8、

8. The control mode is composed of the IPC computer and +ICMC series industrial intelligent module, the control precision is high, the acquisition data is fast, the anti-interference ability is super, the maintenance rate is low, high stability and high reliability.

Related literature

ZL 2009 2 0223715.8 High temperature thermal gravimetric analyzer