PBD Thermal Conductivity Tester (plate method)

PBD tester has a number of patented technology(ZL 2007 2 0092781.7、ZL 2007 2 0092610.4), have been designed according to ASTM201、ASTM202,which are applicable for testing low thermal conductivity of refractory fibers, heat insulation materials and dense refractories,ect. By the principle of one-dimensional stable-state thermal conduction.

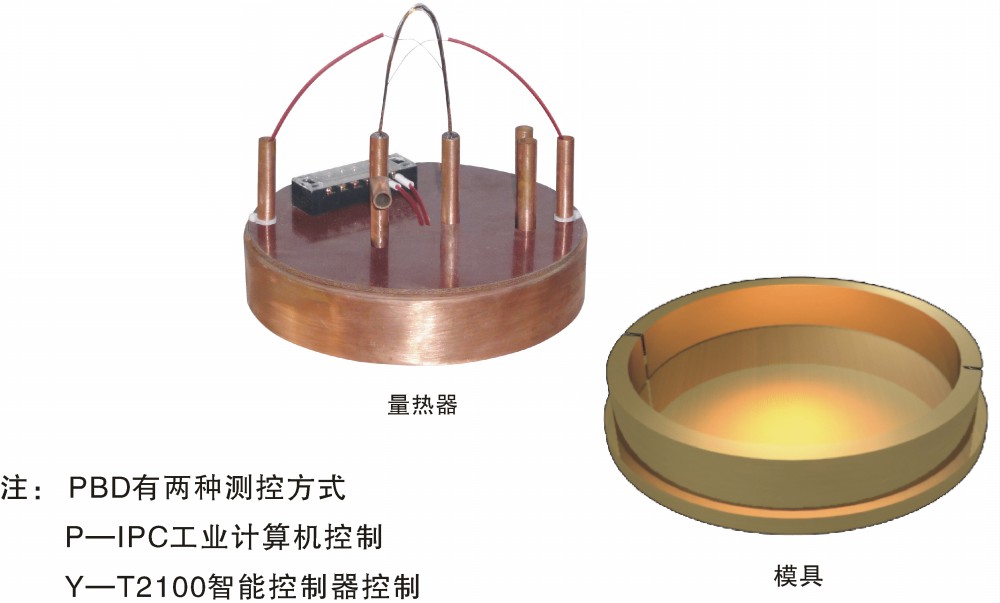

calorimeter

mould

Note:PBD has two control modes

P---IPC industrial computer control

Y---T2100 intelligent controller control

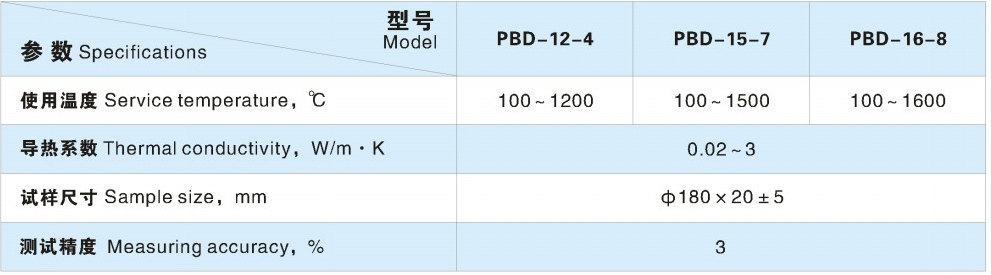

Main technical parameters

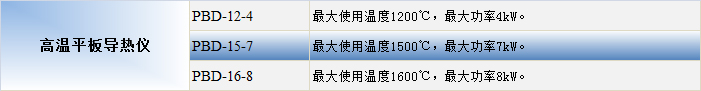

Mainstream model equipment selection guidance:

Maximum use temperature

maximum power

PBD tester have been designed according to YB/T4130,which are applicable for testing low thermal conductivity of refractory fibers, heat insulation materials and dense refractories,ect. By the principle of one-dimensional stable-state thermal conduction.This instrument was determined by Q, T obtained the thermal conductivity

The plate method is used to test the thermal conductivity(0.01~3.0 W/m•k) of insulation board, insulation bricks, insulation materials, fireclay and high alumina refractory products and a variety of unshaped refractory materials at 200~1200℃.

Equipment performance description

1. PBD12 silicon carbide bar heating, PBD15, PBD16 silicon molybdenum bar heating.Patent No:ZL 2007 20092610.4 and ZL 2007 20092781.7

2. Sample size: φ180×(20±5)mm

3. Fully automatic control by IPC,software using Windows system, real time dynamic recording test results, the whole process can be playback,the test data were stored in a ACCESS database mode and can query at any time using the third party software.

4. The whole data can be effectively eliminated when the temperature difference is zero, which can effectively eliminate the error caused by the lag of the artificial measurement and other measurement errors.

Standard

YB/T 4130 2005 Refractory materials -- Determination of thermal

Patent:

ZL 2007 2 0092610.4 Thermal conductivity coefficient tester

of water flow plate method

ZL 2007 2 0092610.4 Thermal conductivity coefficient tester

of water flow plate method