DIL Full-automatic High-temp. Dilatometer (Vertical furnace)

Vertical differential thermal expansion instrument, differential test principle, according to GB/T 7320 Refractory materials-Determination of thermal expansion-Push rod method. Suitable to determine heat expansion ratio and coefficient of nonmetal materials blew 1700℃.

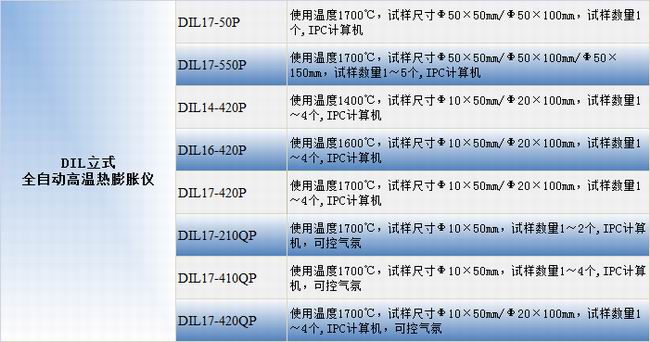

Mainstream model equipment selection guidance:

Use temperature

Sample size

number of specimen

RPZ/DILProduct selection guide

Product structure:RPZ dilatometer DIL dilatometer

Test temperature: 800、1000、1200、1300、1400、1500、1600、1700、1800

Sample size: Φ10×50、Φ20×100、Φ50×50、Φ50×100、Φ50×150

Number of samples: one sample, 2 samples, 3 samples, 4 samples, 5 samples

Test atmosphere: air atmosphere, Q controlled atmosphere

Measurement and control method: Digital instrument Y, LCD screen T, IPC microcomputer P

This equipment according to GB/T7320-2008 and QB/T1547-1992 test standard, mainly used to test the high-temperature expansion of solid inorganic material, metal and nonmetal materials.The application of investment casting shell and core, raw materials, ceramic glaze, porcelain clay, glass, graphite, carbon and other materials are more widely. Obtain material’s line variation (volume), line expansion coefficient and expansion rate, can choose to use professional software to test the softening temperature, sintering kinetics, glass transition temperature, material phase change, density change, rate controlled sintering (RCS).

Instrument characterization:

1. Measurement method:Differential top rod measurement.The static friction force of the top rod is less than 0.02N, and the top rod follows pressure as a fixed value, the deformation is measured by differential method;

2. Top bar and sample tube use high purity corundum products with aluminum oxide content in 99.5%

3. Sintering atmosphere: air atmosphere, controlled atmosphere, pre vacuum

4. Heating: electric heating by silicon molybdenum rod

5. The measuring mechanism consists of a high precision non elastic displacement sensor and an imported linear guide rail pair.

6. Special water cooling circulation system, effective protection measurement system

7. The sample has wide applicability, which is suitable for the test of large sample and multi sample.

8. The control software based on Windows system, automatic calibration, data storage, data analysis, dynamic drawing "Expansion value -temperature, expansion ratio- temperature, expansion coefficient- temperature, temperature-time” curves.Open database can be used to analyze the sintering process with third party software.

9. Professional computer +ICM control module measurement and control, liquid crystal display, printer.

Standard:

GB/T 7320-2008 Refractories - Determination of thermal expansion