HSST Full-automatic Hot Stress and Strain Tester

Mainly used to test the stress - strain properties of inorganic nonmetallic materials, such as refractory materials,can also be used to determine the static Young's modulus, the plastic temperature of the material, the starting temperature of viscous flow, the modulus of rupture at high temperature and other high temperature mechanical properties, is the ideal equipment for material’s research and test.

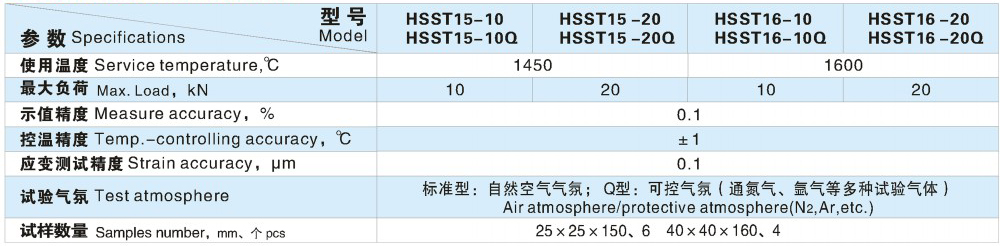

Main technical parameters:

Heating-furnace: electric heating furnace with the lining using mosaic structure. The lining from the inside to the outside are used 1800℃ high temperature energy saving material,1500℃ heat-barrier material and 1000℃ heat-insulating material;the heating element is arranged on both sides of the furnace hearth, adopt U type Si2Mo, one time can test six 25mm x 25mm x 150mm samples or four 40mm x 40mm x 160mm samples, the average temperature in the test area is less than 10℃.

Tester: upper load,rigid frame structure, Germany imported ball screw and servo motor drive,high precision constant stress or displacement loading control, the standard maximum load 10kN, indicating accuracy of 0.5 values, preset standard loading rate of (0.15 + 0.015) or MPa/s (0.05 + 0.005) MPa/s .

Deformation system: contact strain measurement system, through the high temperature rigid material contact with the contact,the deformation of the tension surface of the sample is transferred to the displacement sensor which is installed on the lower part of the furnace, standard displacement deformation is 0-10mm, linearity is 0.05%FS.

Loading platform:

1. ZL 2011 2 0034751.7 Patented loading template

2. Three point bending device is composed of two braces and one pressure bar,the braces and bar are parallel to each other. The distance of the braces is 125mm±0.5mm,the pressure bar is placed at the center point of the two braces,accurate to ±0.5mm;

3. Pressure bar, loading template material:HMOR15 standard configuration Si3N4-SiC;HMOR16 standard configuration R-SiC;If SiC does not adapt to the test temperature,exclusive material is provided;

4. The brace shall have a length not less than 5mm greater than the breadth of the width of the sample and a radius of curvature of (5±0.5)mm,the braces shall be examined periodically to ensure that their radii remain the limit;

5. Two braces should be at the same horizon level,the distance should be measured at room temperature, accurate to ±0.5mm.

Measurement and control system:

1. Using high precision and anti-interference measurement and control platform, commercial computer display, Multi windows professional application software,automatic control the temperature, deformation and loading process, real-time record test results and can replay the testing process.,database management, can query at any time using third party software.

2. Hardware and software dual filter anti - jamming processing,temperature, pressure signal and sample position accurate acquisition in high temperature electromagnetic environment.

3. When start,automatic operation and record drawing "temperature - time" , "stress - time", "strain- time","stress - strain"curves. Controlled atmosphere of HSST-Q series, force loading, deformation measurement, and the sample feeding table patented dynamic seal, and carry out performance testing of materials in other atmospheres.

Related literature:

ZL 2011 2 0034751.7 Patent sample table

ZL 2013 2 0447243.0 A loading mechanism of large tonnage refractory material mechanical performance testing machine

ZL 2012 2 0580828.5 Dynamic sealing force value transfer device for high temperature mechanical testing machine

(For more information, please call the Advisory)