HAT Hot Abrasive Tester

AT international advanced technology for testing the wear resistance and impact resistance of refractory materials in the heating or non heating state.

Mainly consists of sample heating furnace (ZL 200820221436.3),specimen bearing mechanism (ZL 200820120642.0),abrasive gun(ZL 200820230870.8),compressed air supply-storing device (ZL 20020230871.2)and tail gas cooling and purifying device(ZL 200820230872.7).

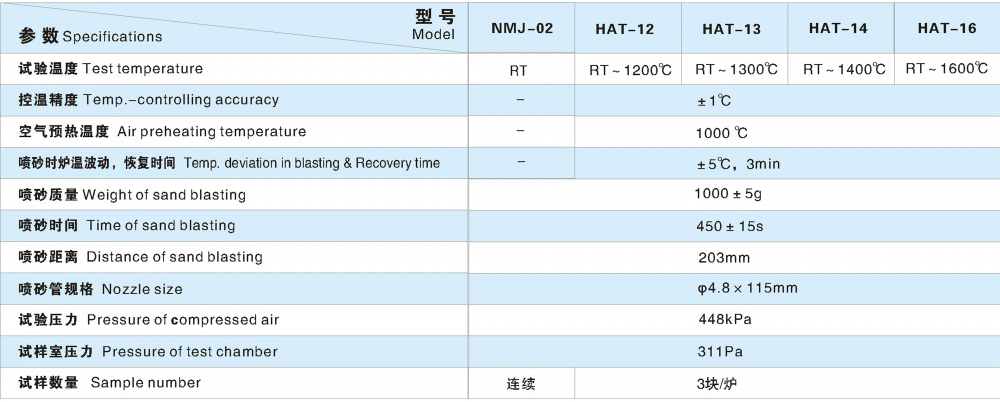

Test principles and basic parameters equivalent to the national standard GB/T 18301《Refractory products - Determination of resistance to abrasion at ambient temperature》,can test the relative wear resistance of non metallic materials at room or high temperature.Air pre heating, furnace temperature control, temperature fluctuation when 450s blasting is not greater than 5℃ and can quickly recover in 3mins.

Multi sample continuous automatic test, can obtain RT~1600℃ wear curve.

Main technical parameters:

Brief introduction of instrument application:

The lining refractories used on industrial furnace such as blast furnace, cement kiln, lime kiln and circulating fluidized bed boiler, due to the material and air impact and friction effect, result the erosion of lining material,equipment leakage and equipment leakage,brought many negative effects to the industrial production.This phenomenon occurs not only in the room temperature, at high temperature,the material developed from rigid to plastic, structure and strength changed, the wear mechanism changes.

As the important physical properties of materials, wear resistance is the ability of refractory material resistance hard material or gas (containing solid material) friction and wear, it is used to evaluate the performance of refractory materials in wear and erosion conditions.

According to the GB/T18301 《Test method for abrasion resistance of refractory materials at room temperature》, ASTM C 704《 standard test method for abrasion resistance of refractory materials at room temperature》, the new generation of products developed on the basis of NMJ-02 tester.Hot Abrasive Tester can meet the RT~1600 ℃ and high temperature wear resistance test.

ZL 2008.2 0221436.3: Sample heating furnace for refractory material abrasion at high temperature

ZL 2008.2 0120642.0:Bearing sample mechanism of refractory material abrasion at high temperature

ZL 2008.2 0230870.8:Abrasive spray gun of refractory material abrasion at high temperature

ZL 2008.2 0230872.7:Tail gas cooling and purifying device of refractory material abrasion at high temperature

ZL 2008 2 0230871.2:Compressed air supply and storage device of refractory material wear test at high temperature

Instrument characterization:

1. The testing machine is mainly composed of compressed air pre heating system, test sample bearing mechanism, sample heating mechanism, abrasive spray gun and tail gas cooling and purifying mechanism.

2. Test principle: under the action of the preheated air flow, a certain amount of wear medium accelerated by injection,the impact heated to the sample at high temperature,after cooling,measure the surface of the sample worn volume.

3. Abrasive gun mechanism adopts a venturi effect in accelerated wear medium, the wear medium injection is stable and reliable.

4. 3 samples / furnace, using automatic or manual sampling control.

5. Compressed air supply and storage mechanism based on the principle of air preheating, during the test, the fluctuation is small and reliable, wear medium injection in the bottom is easy to collection.

6. The furnace adopts tail gas cooling and purifying system to achieve the effect of dust removal and environmental protection.

Patent:

ZL 2008.2 0221436.3: Sample heating furnace for refractory materialabrasion at high temperature

ZL 2008.2 0120642.0:Bearing sample mechanism of refractory material abrasion at high temperature

ZL 2008.2 0230870.8:Abrasive spray gun of refractory materialabrasion at high temperature

ZL 2008.2 0230872.7:Tail gas cooling and purifying device of refractory material abrasion at high temperature

ZL 2008 2 0230871.2:Compressed air supply and storage device of refractory materialwear test at high temperature

Standard:

GB/T18301-2012 《Test method for abrasion resistance of refractory materials at room temperature》

Literature:

“Discussion on a new method of wear resistance test at high temperature ”authors: Huang Zhongming,Gao Jianrng,Li Yonggang,------《Refractory》2010.6

“A New test method for HAT”authors:Li Yonggang,Liu Ke------《China‘s Refractories》2011.3