Microcomputer controlled compressive strength tester

1 Instrument synopsis

Mainly used in the compressive strength test at room temperature

High precision digital servo valve, force closed loop control function, can achieve equal load or equal stress rate loading,high control precision and good reliability.

Using computer to realize the electronic measurement, automatic test, automatic calculation and print report

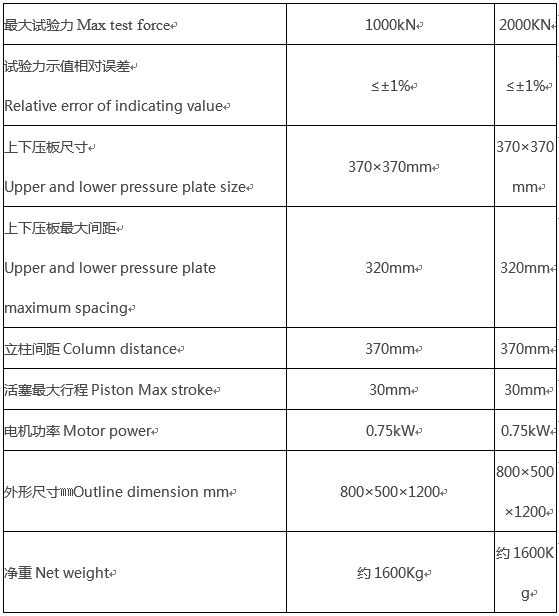

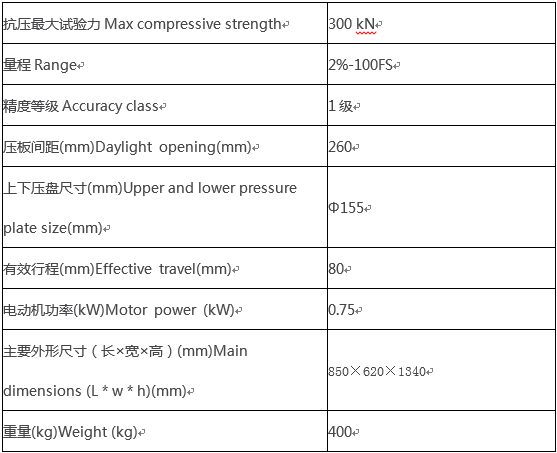

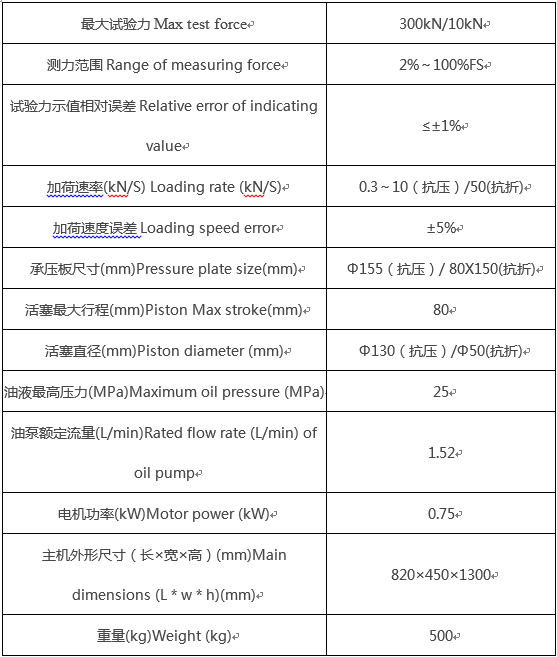

2 Technical parameter

Maximum test force 1000KN, computer automatic control

The maximum test load 300KN, manual loading, automatic test, liquid crystal display intelligent controller

CCS-300/10P:Bending and pressure integrated machine,double working position of the test space, space saving and easy to operate,the max pressure force 300KN, the max bending force 10KN, computer automatic control.

3 Detailed description

Hydraulic system

Through the high pressure pump driven by the motor, the hydraulic oil in the oil tank is driven into the oil path, through the one-way valve, the high pressure oil filter, the pressure difference valve group and the servo valve entry cylinder.The computer sends out the control signal to the servo valve, controls the opening and direction of the servo valve, thus controls the flow rate of the oil entering cylinder, and realizes the control of constant velocity test force.

Force measuring system

1. High precision amplifier and A/D converter, not divided into files in the whole process, real-time display load, peak load speed and strength;

2. PID closed loop control strategy to achieve constant speed loading, real-time display loading curve

3. Automatic interval timing and continuous testing

4. Query, print test results flexible and convenient

Safety protection device

When the test force exceeds 3% of the maximum test force , overload protection, pump motor stop.

4 Related literature

Standard:

GB/T 5072-2008 Refractories-Determination of cold compressive strength

GB/T 3001-2007 Refractory products - Determination of modulus of rupture at ambient temperature