Hot MOR Tester

Authorized measuring instruments, mainly used to determine bending strength at high or room temperature. Framed rigid structure, double lead drive screw, stepless frequency conversion control ,automatic constant vertical loading,high precision pull pressure sensor,intelligent measurement and control platform,display by IPC industrial computer and the software based on Windows.

In the ATLIRR software support, automatic heating, heat preservation, sample delivery, loading, data processing, report printing, paper records, database management, meet the requirements of GB/T3002, ISO5013, ISO5014 and other standard techniques. Carbon containing materials are also applicable.

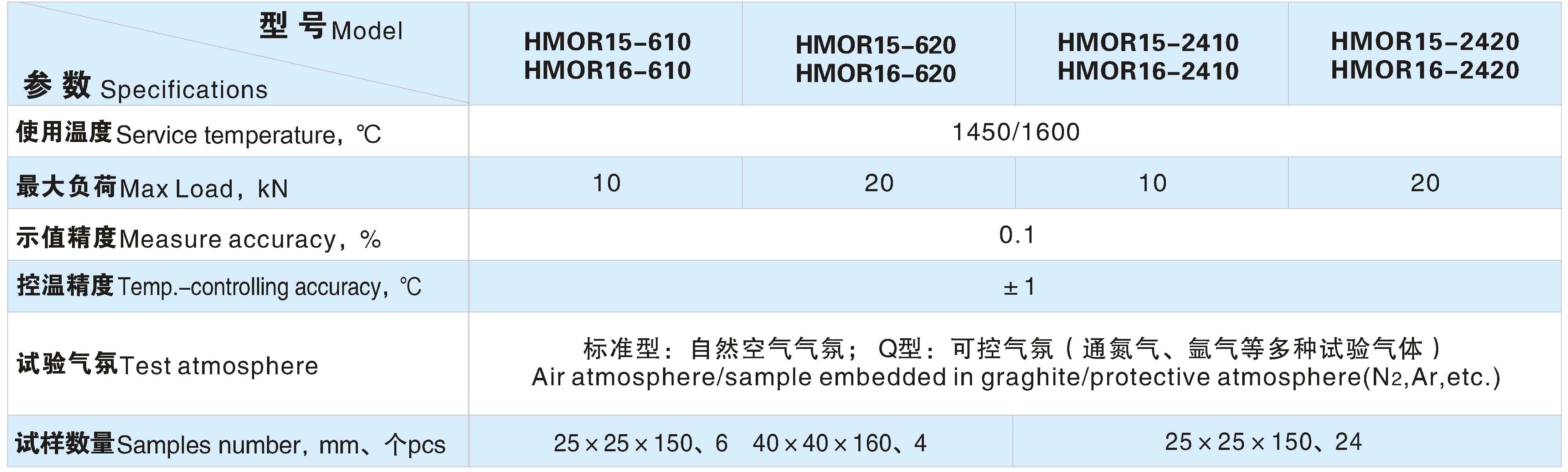

Main technical parameters:

Detailed description:

Brief introduction of instrument application:

HMOR tester according to standards GB/T3002、GB/T13243、ISO 5013 refractory products-determination of modulus of rupture at high & room temperature. Using three-point bending technique(Electronic frequency conversion or servo constant stress-displacement) to test refractory’s modulus of rupture at high or room temperature.

For carbon products,HMOR series Hot MOR tester, providing the patent technology of sagger embedded carbon.

Controlled atmosphere of HMOR-Q series, can prevent the oxidation of carbonaceous materials and carry out performance testing of materials in other atmospheres.

HMOR can provide:

1. 6 samples(25mm×25mm×150mm) or 4 samples(40mm×40mm×160mm) per test

2. 24 samples(25mm×25mm×150mm) or 12 samples(40mm×40mm×160mm) per test

3. Continuous work(manual intervention or full automatic non-stop testing)

Instrument characterization:

1. Main engine adopt portal frame construction, Multistage mechanical deceleration and vertical beam rigid mechanical loading;

2. AC frequency control,imported inverter,controlled loading in test;

3. Using integrated miniature motor,electric mechanism, automatically complete the process of sampling;

4. Using high precision and anti-interference ICM industrial control module, control software using PID algorithm;

5. Pressure value acquisition cycle is less than 2ms,Control period is less than 10ms,real time follow-up control, control accuracy is 100% higher than similar products. The loading force value feedback control using dual PID variable frequency control.

6. The loading device satisfies the standard loading rate(0.15 + 0.015) MPa/s and (0.05 + 0.005) MPa/s, can uniformly applied to more than 1 MPa/s and less than 0.01MPa/s,when the sample is broken,record and indicate the maximum load and the time load , and the accuracy of the indicator is 0.5.

7. When start,automatic operation and record drawing "temperature - time" and "stress - time" curves;

8. Fully automatic control by IPC,software using Windows system,automatic control temperature and loading process,real time dynamic recording test results, the whole process can be playback,the test data were stored in a ACCESS database mode and can query at any time using the third party software.

9. Hardware and software dual filter anti - jamming processing,temperature, pressure signal and sample position accurate acquisition in high temperature electromagnetic environment.

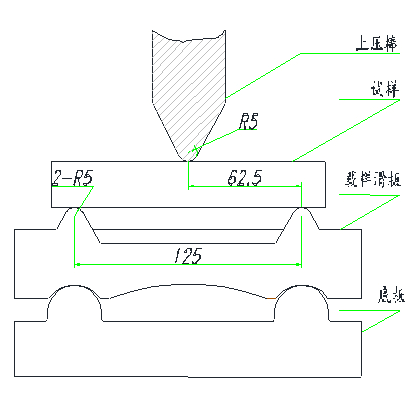

Three point bending device

:

上压棒:Upper pressure bar

试样:sample

载样滑板:Loading template

底板:Bottom plate

1. Three point bending device is composed of two braces and one pressure bar,the braces and bar are parallel to each other. The distance of the braces is 125mm±0.5mm,the pressure bar is placed at the center point of the two braces,accurate to ±0.5mm;

2. Pressure bar, loading template material:HMOR15 standard configuration Si3N4-SiC;HMOR16 standard configuration R-SiC;If SiC does not adapt to the test temperature,exclusive material is provided;

3. The brace shall have a length not less than 5mm greater than the breadth of the width of the sample and a radius of curvature of (5±0.5)mm,the braces shall be examined periodically to ensure that their radii remain the limit;

4. Two braces should be at the same horizon level,the distance should be measured at room temperature, accurate to ±0.5mm.

Related literature:

Related literature:

GB/T 3002-2004 Refractory products-Determination of modulus of rupture at elevated temperatures

GB/T 3001-2007 Refractory products-Determination of modulus of rupture at ambient temperatures

Patent:

ZL 2011 2 0034751.7 Loading template for measuring deformation of specimen by three point bending test

Literature:

“Standardization of the production of Hot MOR Tester”authors: Li Yonggang, Tan Lihua ------《Refractory》2003

“Stress increasing rate of modulus of rupture test at elevated temperature"authors: Han Yuexiu, Li Yonggang ------《Refractory》1995